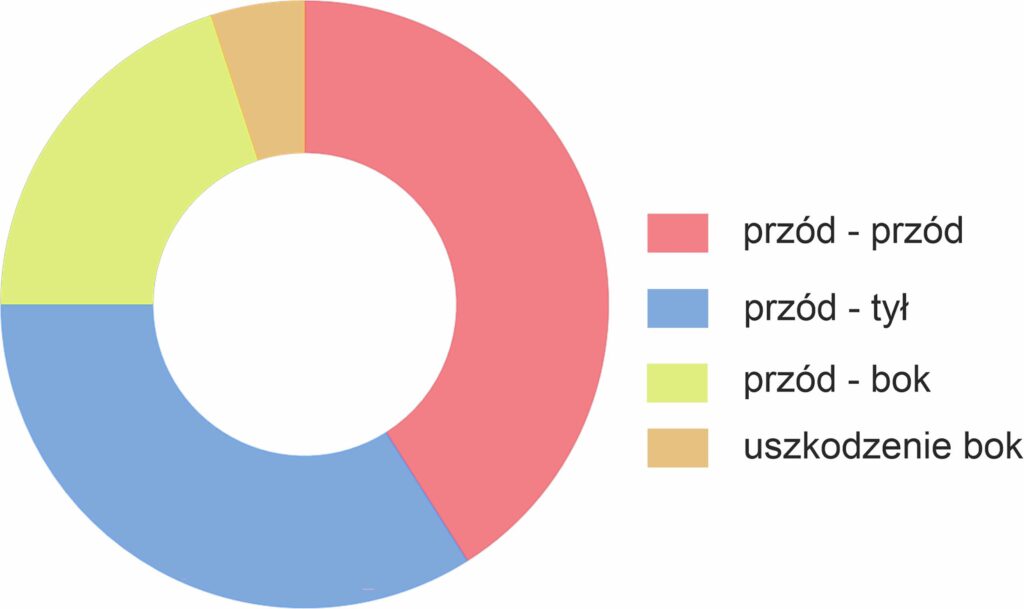

One of the most important components of most types of commercial vehicles is the driver’s cab. Nearly half of all collisions and accidents involving trucks involve damage to the front part of the vehicle: invasions and head-on collisions, in which, in addition to twisting the frame, the cab is also destroyed.

Fig. Incidence of vehicle collision types. (BR)

Position planning

As is usually the case, there are different, sometimes conflicting opinions on the choice of how to handle cab-related traffic damage. However, given the significant size and weight, it begs the thought that the matter should be approached comprehensively and extremely carefully. It is true that various more or less ad hoc repair methods are used, resulting in the effective restoration of the structure to its original shape, but economy and ergonomics must not be forgotten. Contrary to appearances, the two terms not only have a similar sound, but are inextricably linked. After all, it is difficult to expect an economical repair without providing workers with conditions where ergonomics allows such facilitation that the time spent on the elimination of the damage can be reduced enough to make the whole operation worthwhile.

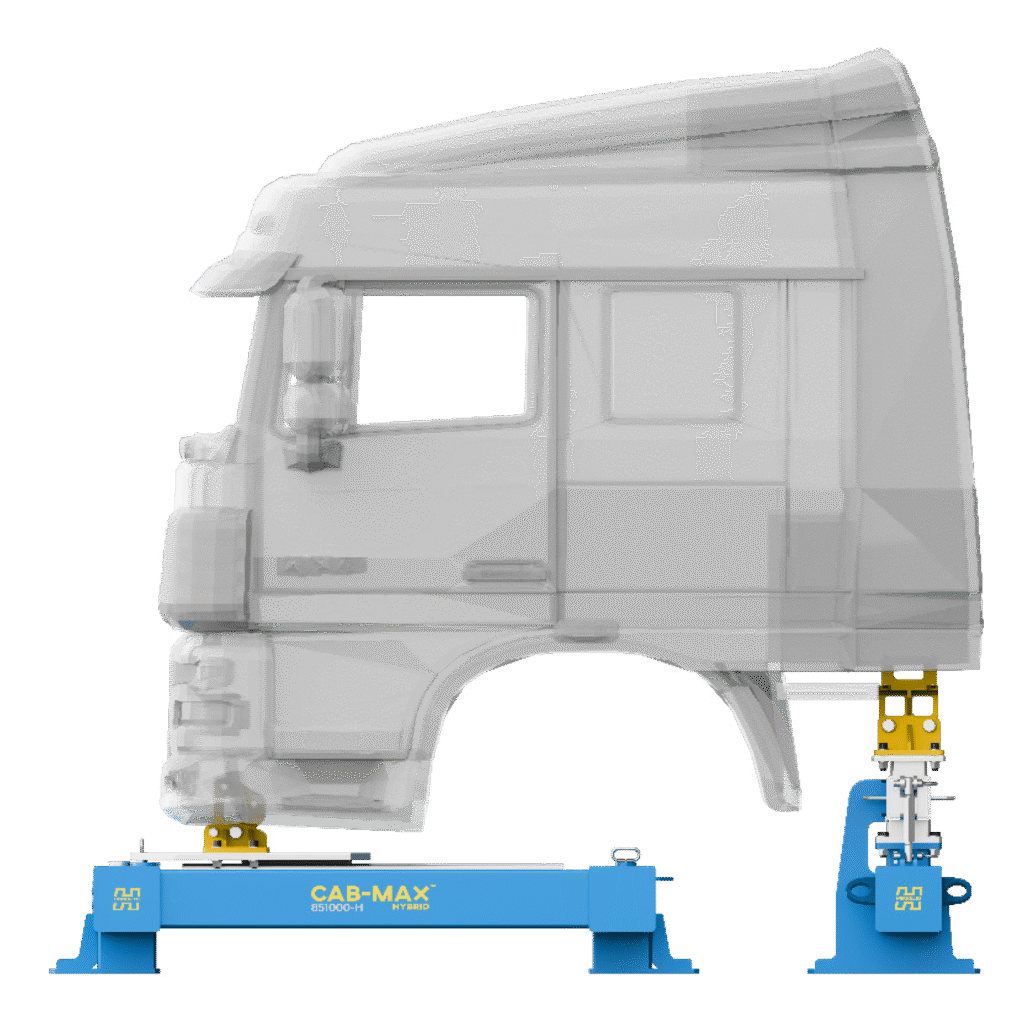

Photo: fixing the cab on the repair stand in the process holders. (Photo: Herkules TRUCK)

Does cabin repair pay off these days?

Answering this question is not easy. Certainly, not every post-accident repair is economically justifiable, and this does not apply exclusively to the issue discussed in this article. Instead, referring to the text above, it can be said with full responsibility that when organizing an accident repair department, everything should be done to make profits from repair services to the fullest extent possible. Expanding on this thought, it is largely on the technologies possessed and the organization of the repair stand that will determine whether, and how much, the company will earn. A separate issue is the degree of expertise and training of the claims staff. In addition, the system for ordering and delivering spare parts also affects time and cost. Having conducted investment and technology training and consulting for years, I sometimes hear absolutely contradictory opinions. Some say it’s not worth taking on cabin repairs, while others make one repair after another. One might ask: how is this possible? Is everyone right, or do those who do the repairs not know how to count? What is the point here…. I have the advantage of having seen hundreds of accident repair services. I am often in contact with companies that I have already advised when planning to build a workshop. It is well known not from today that sometimes the darkest under the lantern and the owner of the service does not always have an objective view of how his company operates. Therefore, it is worthwhile from time to time to perform a more or less official technological and economic audit, in order to work and earn in the real world, and not to live in imaginations and illusions. Why this argument? In my opinion, it fits perfectly with the answer to the question: is it worth repairing cabins?

Which system to choose?

Turning to specific technological solutions, it should be recalled that a lot depends on the stage at which you expand your business to include a cabin repair division. As with the straightening of frame structures, this is best done at the technology planning stage of the entire service. However, this is not a sine qua non and, in fact, can be done at any time. The devices attached to the grate in the floor are very ergonomic and efficient. For this, you can use the grate area intended for everyday frame repairs, or create a so-called “small grate” with external dimensions of about 5 x 5 m, specifically for cabins. If there is no fixing grate, it is possible to make a system of anchors for repair accessories and pull towers. However, this is in a sense a substitute solution. Regardless of the detailed solutions for fixing in the floor, this repair equipment can be conventionally divided into three types:

- framework,

- traverse,

- Frame with floor straightening system.

The frame system allows the cab to be fixed and braced at technological points so that repair with hydraulic towers is possible. It is a system somewhat similar in operation to the repair frames of vehicles up to 3.5t and does not seem to require special discussion. However, it should be noted that mounting on a compact frame significantly blocks access to the lower part of the cab.

A more interesting solution is the traverse system. The undoubted advantage of such a solution is the considerable mobility of the system’s components and the not too large space required for its storage, which in small services conducting this type of repair only on an ad hoc basis can be of key importance. Another advantage is the considerable space for carrying out additional repair activities of the floor plate.

The inconvenience for this is the lack of the possibility of using a special fixture of brackets that provide a template for the shape of the floor plate.

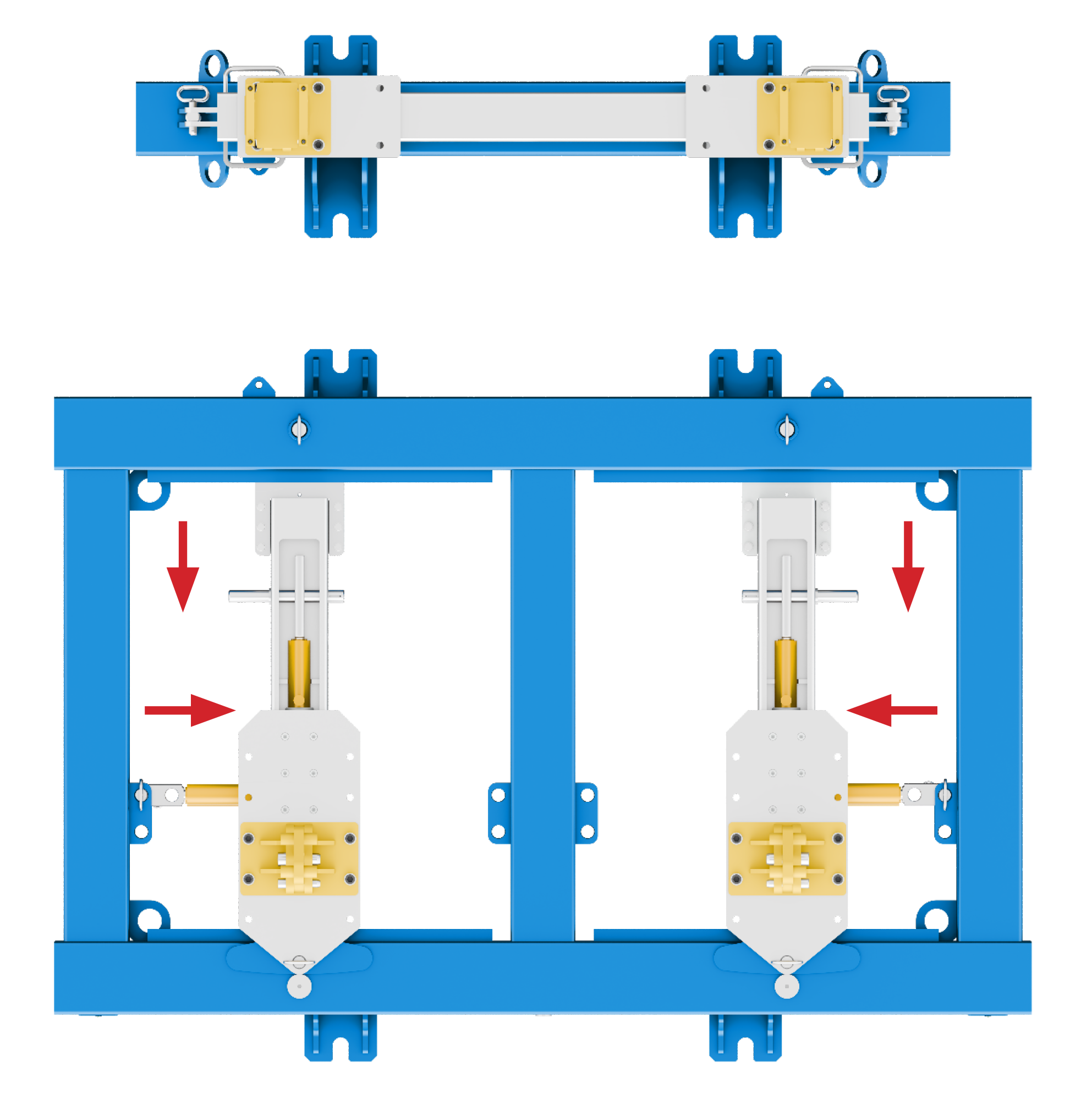

Fig. Frame system with floor straightening capability. (HERKULES TRUCK)

The cab repair system, which is a combination of a frame and traverse system, is additionally equipped with a hydraulic floor plate repair system. The design of this type of equipment also allows the use of bracket systems for individual cab models. The effect of this is to obtain a pattern of the chassis shape, particularly highlighting the hinge and striker attachment points. It’s the four most important zones of the chassis that determine whether or not the cab for you mount to the vehicle frame.

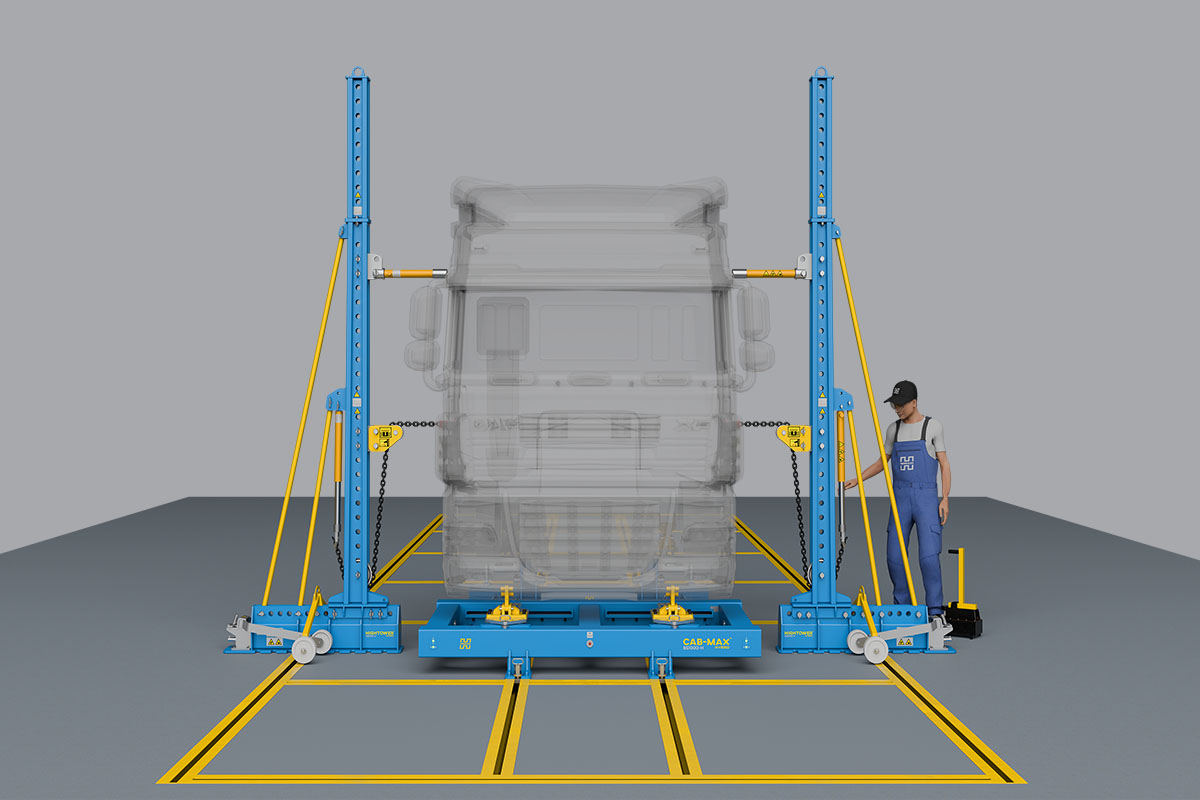

Hydraulic towers and other instrumentation

Regardless of the choice of attachment system, the same high towers are used in all cases. The choice of attachments depends solely on financial possibilities and current needs. Optimally, in each case, the kit includes two towers pulling a cylinder system for repairing the floor plate and a set of hydraulic spreading tools. It is necessary to have a set of brackets for attaching the cabs to the frame, as well as sheet metal pulling brackets attached to the cab body.

Photo: HIGHTOWER HYBRID™ high towers (Herkules TRUCK)

Repairing body panels requires the use of modern tools. It is also necessary to use inverter welders and tools for disconnecting components. The use of soldering irons is also standard these days. A sheet metal gauge is also useful. All these technologies skillfully used by trained workers are also a condition for the profitability of the whole process.

Additional equipment of the station

A repair stand is not just about the equipment and the fixing system and the additional equipment you have. Proper logistics must be taken care of. Starting with adequate storage space (items of considerable size), to solutions that allow ergonomic and safe disassembly, removal, transfer and assembly of finished booths and their individual components.

After the repair, it is necessary to carry out paint preparation work, which, with the sizable size of the cab, requires adequate space, work platforms and similar facilities. It’s worth thinking about transport carts to carry the cabs through the process from pre-painting preparation to delivery of the painted and pre-assembled cab to the assembly station on the vehicle.

In order for the appropriate economic mechanisms to work that bring measurable financial results, i.e. profit, all aspects related to the organization of the cabin repair service should be met and adjusted. In addition to those purely technical ones related to the selection of equipment, it is still necessary to remember about the proper implementation and training of employees. This is as important and profitable as a good repair system.

read more