Commercial vehicle cab repair system

CAB-RAM™, CAB-TECH™, CAB-MAX Hybrid™.

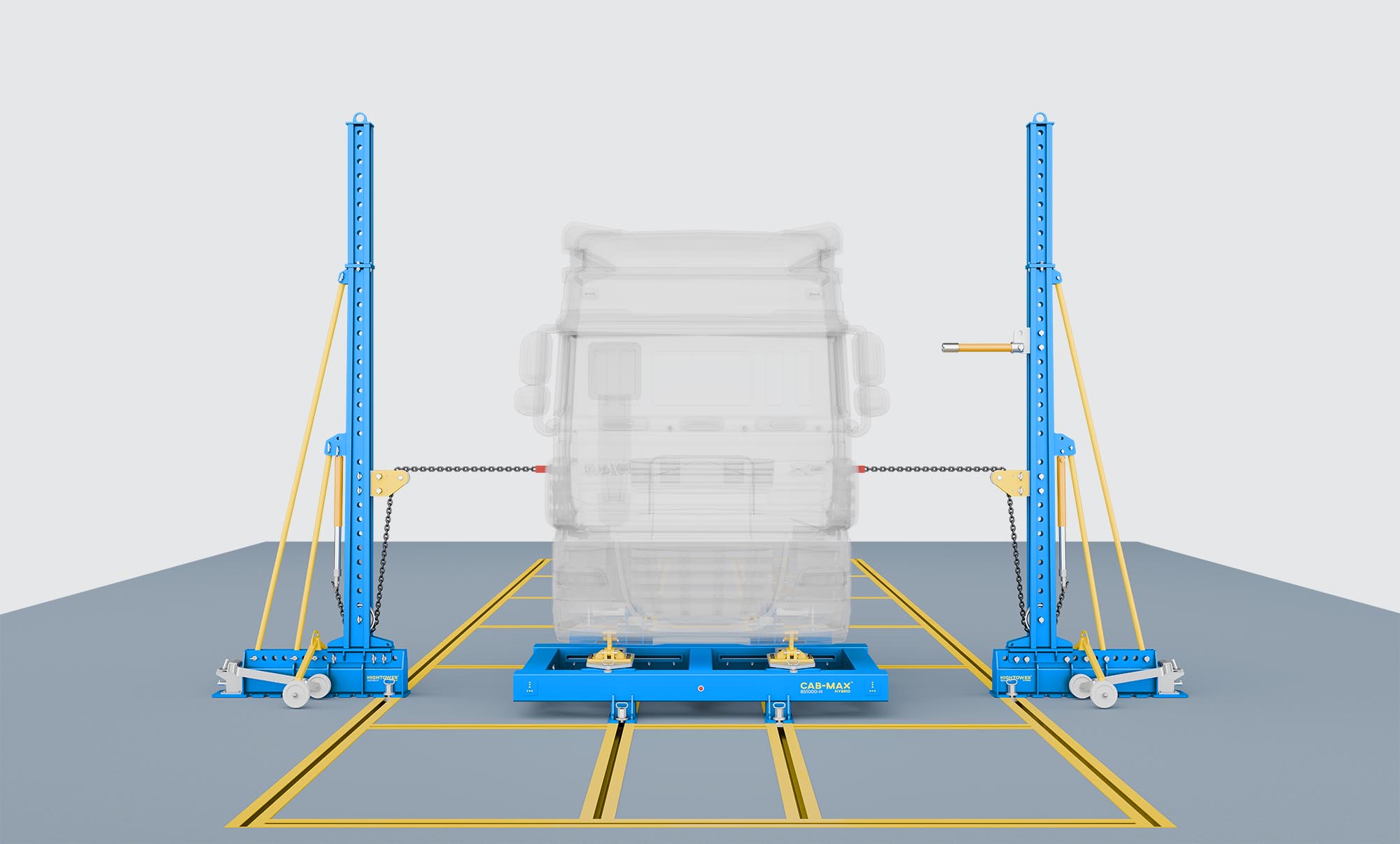

The design of the CAB-TECH™ and CAB-MAX™ devices allows the use of bracket systems for individual cab models with simultaneous hydraulic support for the repair of the chassis. The effect of this is to obtain a pattern of the chassis shape, particularly highlighting the hinge and striker attachment points. It’s the four most important zones of the chassis that determine whether or not the cab for you mount to the vehicle frame. Regardless of the choice of attachment system, the same HIGHTOWER™ high towers are used in all cases.

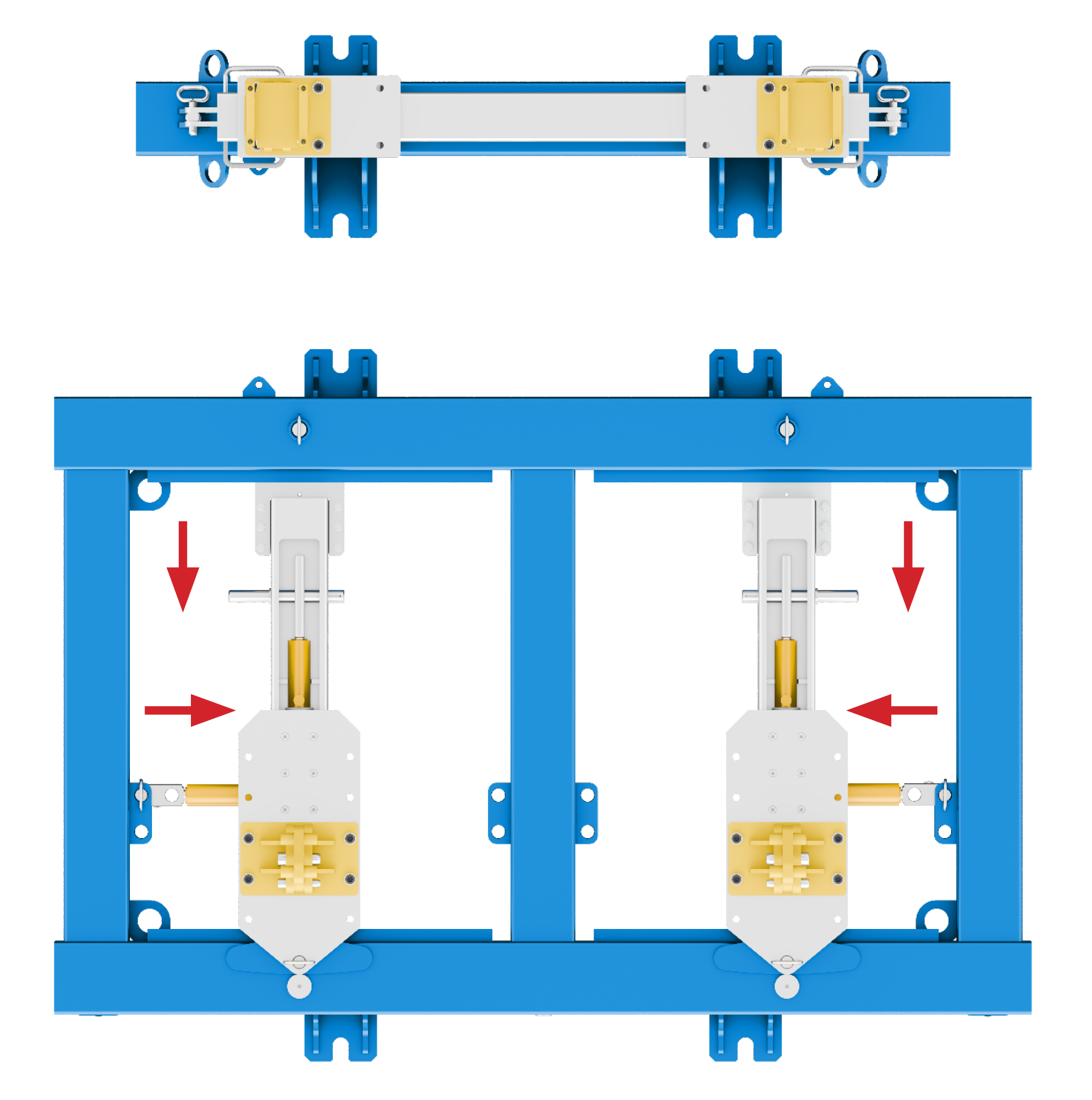

The design of the CAB-MAX hybrid™ enables the use of brackets tailored to specific cab models, while providing hydraulic support when straightening the vehicle cab. This makes it possible to reproduce the shape, with special attention paid to the attachment points of the hinges and lugs. It is these four key zones that determine whether the cab can be properly mounted on the vehicle frame.

The CAB-MAX hybrid™ cab repair unit can be equipped with an electronic control system for the repair process. This system makes it possible to measure the position of the front brackets mounted on the unit. The CAB-MAX control™ version allows real-time monitoring of the process of setting the base points in the cab area, where the hinges connecting it to the vehicle frame are mounted.

Which system to choose?

The choice of system depends on the stage at which you expand your business to include a cabin repair department. As with the straightening of frame structures, this is best done at the technology planning stage of the entire service. However, this is not a condition sine qua non and in fact it can be done at any time. The devices attached to the grate in the floor are very ergonomic and efficient. For this, you can use the grate area intended for everyday frame repairs, or create a so-called “small grate” with external dimensions of about 5 x 5 m, specifically for cabins. If there is no fixing grate, it is possible to make a system of anchors for repair accessories and pull towers. However, this is in a sense a substitute solution.

CAB-RAM™

CAB-TECH™

CAB-MAX Hybrid™

The innovative CAB-MAX control™ system– how does it work?

Operation of the control system involves tracking the movement of the cabin hinge mounting plates and determining their position using a grid of electronic sensors. The measurements are converted into a system of light indicators. LEDs on the control panel indicate the distance from the reference position. Red indicates a distance greater than 100 mm, orange indicates 50 to 6 mm, and green indicates 5 to 0 mm.

Improving ergonomics and safety

In standard repair systems, organoleptic inspection and monitoring of the repair process can be difficult because the cab often obscures the pin seating area. The innovative CAB-MAX control™ solution solves this problem. In addition, the ability to remotely monitor the control panel greatly improves operator safety.